|

FLEXOGRAPHIC LABELS

(Most efficient for longer runs)

Most of our labels are produced on a flexographic press Most of our labels are produced on a flexographic press

We print with ink, mixed according to the PMS system. Each colour requires a flexible photo-polymer plate and film. For superior results a few design parameters should be kept in mind. For instance, registration should allow for some shifting (up to 1/32") to occur. Long straight lines or borders should not be less than a 1 point line width. Fine type or type less than 5 point size should be avoided, and half tones will reproduced at a 100 line screen.

Gloss or matte over-laminate can be applied to give more durability and protect the ink.

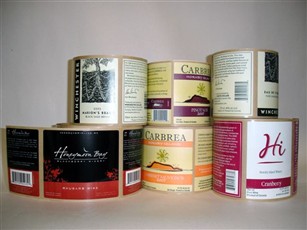

Wine Labels

A number of die sizes are suitable for products such as wine, which require a front and back label on the same roll. Either a matte or glossy over-laminate will protect the label from staining or abrasion.

This is by far the most cost efficient way to produce large runs of labels. Print quality is superior as is brightness and depth of colour. Initial setup charges are higher but is a once only charge. (plates/film/artwork)

AVAILABLE STOCKS FOR FLEXOGRAPHIC PRINTING:-

- Semigloss and High gloss permanent and removable adhesive paper

- BOPP - Polypropelene Plastic available in white or clear and usually protective Overlaminated

- Polyesters - Mylar

- Fluroescent colours

- Primax plastic (better than vinyl)

- Overlaminate both in clear gloss and clear matte available

- Reflective Silver

- Clear Electrostatic (non adhesive sticker for glass etc)

|